Hinge Boring for Brushy Creek Custom Doors

Brushy Creek Custom Doors section index

Concealed Hinge Boring for Cabinet Doors

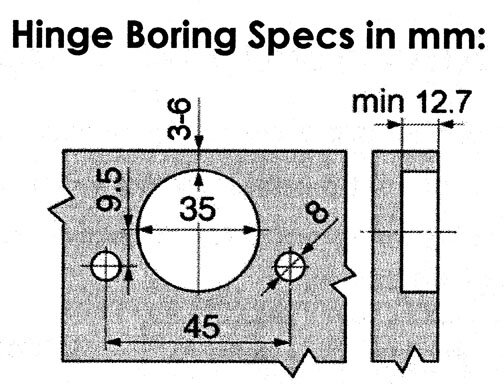

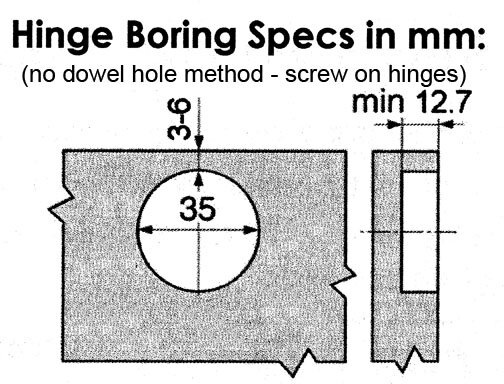

Hidden hinges are definitely the most popular hinge choice in today's kitchens and furniture building. Close the door, you do not see the hinge. And there are many specialty type hinges for all kinds of fancy applications, wider degrees of opening, blind corners, pie-cut, and other applications. Almost all concealed European hinges seem to agree on the 35mm dia. hinge cup hole. Then there are two boring patterns: with dowel holes, and without dowel holes. Brushy Creek Custom Doors bore their hinge holes in the Blum Boring Pattern. Many other brands of concealed hinges make their hinges to match the Blum pattern.

You can request to have your doors bored with the dowel pattern for press-in hinges with the pre-attached plastic dowels. This is the more popular choice. You would push or tap your hinges into your door GENTLY with a rubber mallet. The will be perfectly aligned, and you do not need to square them to the edge of the door yourself. When choosing the No-dowel pattern, this is what you would do if you are planning on re-using hinges you have, and then you should take a square to them when predriling for your two small screw holes. This is referred to as a screw-on hinge. A press-in hinge and screw-on hinge are the same hinge, one just has the pre-attached plastic dowels.

Here are diagrams of what we just explained

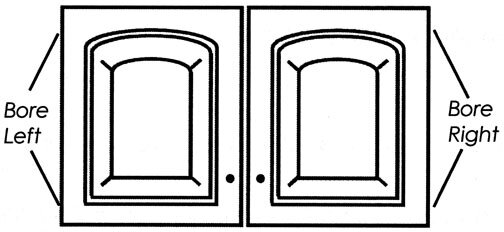

On square design doors, slab doors, and shaker style doors, doors that have an identical top and bottom, you do not need to specify left or right hinge boring. You can easily flip a door over to achieve either. But on Cathedral and Arch top doors, you MUST specify left (BL) or right (BR) boring. Or bored as a pair (BP) for pairs of doors. To review Door Style Selections, please see that link.

Note: when special hinge cup placing, such as 4" on center from the top and 5" on center from the bottom, you just defined the top of the door. So BL and BR becomes important again.

Another parameter that you get to select is the edge boring distance. You can choose 3mm (1/8") or 6mm (1/4"). Boring is done in 3mm or 6mm distances. What is the difference?

When you have face frame cabinets, and your goal is the ever popular 1/2" overlay on the face of those frames, SELECT the 3mm boring. This conveniently provides for 1/2" overlay when using 1/2" overlay hinges. We have some choices of hinges to offer you too.

If you have frameless cabinets and need a 5/8" overlay, also called Full Overlay, to hide the 5/8" thick sidewalls of your cabinets, SELECT the 6mm edge distance option. With most Blum and other brands of hinges, you will get a 5/8" overlay. If you need a greater overlay because you have 3/4" thick sidewalls, Blum does have an extended overlay hinge that gives you 2mm more of overlay. If you have 5/8" of overlay on a 3/4" thick cabinet box wall, that is okay. You do not need to overlay the whole thing. Some applications may call for it, but 5/8" is generally good.

So for face frame cabinets, choose 3mm. For frameless cabinets, better to choose the 6mm. What the difference does is pull the door more over the edge as the distance gets larger, thus MORE overlay.

For concealed hinge selections that we offer, select that link.

Here are some photos of actual hinge boring

Brushy Creek Custom Doors web pages:

3D Laminate Pages: Brushy Creek Summary (info on how to order also) | Raised Panel Doors (inside radius corners) | Raised Panel Doors (square inside corners) | Raised Panel Doors (options to inside corners) | Slab Cabinet Doors and Drawer Fronts | Shaker Style Doors (sunken flat panel) | Door Design Styles (the look from the front) | 3D Laminate COLORS | Frame only and Mullion Doors | Fluted Fillers | Molding options | Wine Racks and Valances | 3D Laminate for Refacing | On-Line Quotation and Ordering Form | MINI on-line Thermal Foil Quotation and Order Form

Wood Cabinet Door Pages: Brushy Creek Wood Kitchen Cabinet Doors | Wood Cabinet Door Designs and Profiles | Wood Cabinet Doors Wood Choices and Options | Wood Cabinet Doors Quotation and Order Form

Common pages to Wood and 3D Laminate Doors: Face Frame and Frameless Cabinets explained | Hinge Boring info | Measuring Advice | Receiving your Doors and Warranty Info